Industrial

Design

Industrial design is the design discipline capable of uniting the creativity of art with industrial manufacturing techniques. It aims to create beautiful and functional products following the technical requirements of production. It works by giving form and appearance to materials in order to create new functional products that meet the needs of the consumer. All phases of industrial design should consider the balance between functionality and esthetics, as well as ensuring that new products respond to ethical, human and also environmental factors.

Why do we

need one?

Industrial design is essential for brands that have consumer products on the market and want to offer new solutions. It analyzes consumer trends and user needs in order to launch attractive and innovative products onto the market. The rapid evolution of the markets requires a constant rethinking of the world of objects that surrounds us. Factors such as sustainability and innovation compel us to design new products capable of improving people's lives. Ultimately, a brand’s success depends on the successful design of their products.

What does it

consist of?

1

Product Design

When we talk about product design, we refer to improving the user experience of the objects that surround us through their industrial design. Product innovation requires a response to a problem, providing formal solutions by improving ergonomics, creating a more attractive appearance, adding a new functionality or simply adapting to a new consumer need. From mass consumption to the luxury sector, industrial design is the ambassador of change, turning mass-produced products into objects of desire.

2

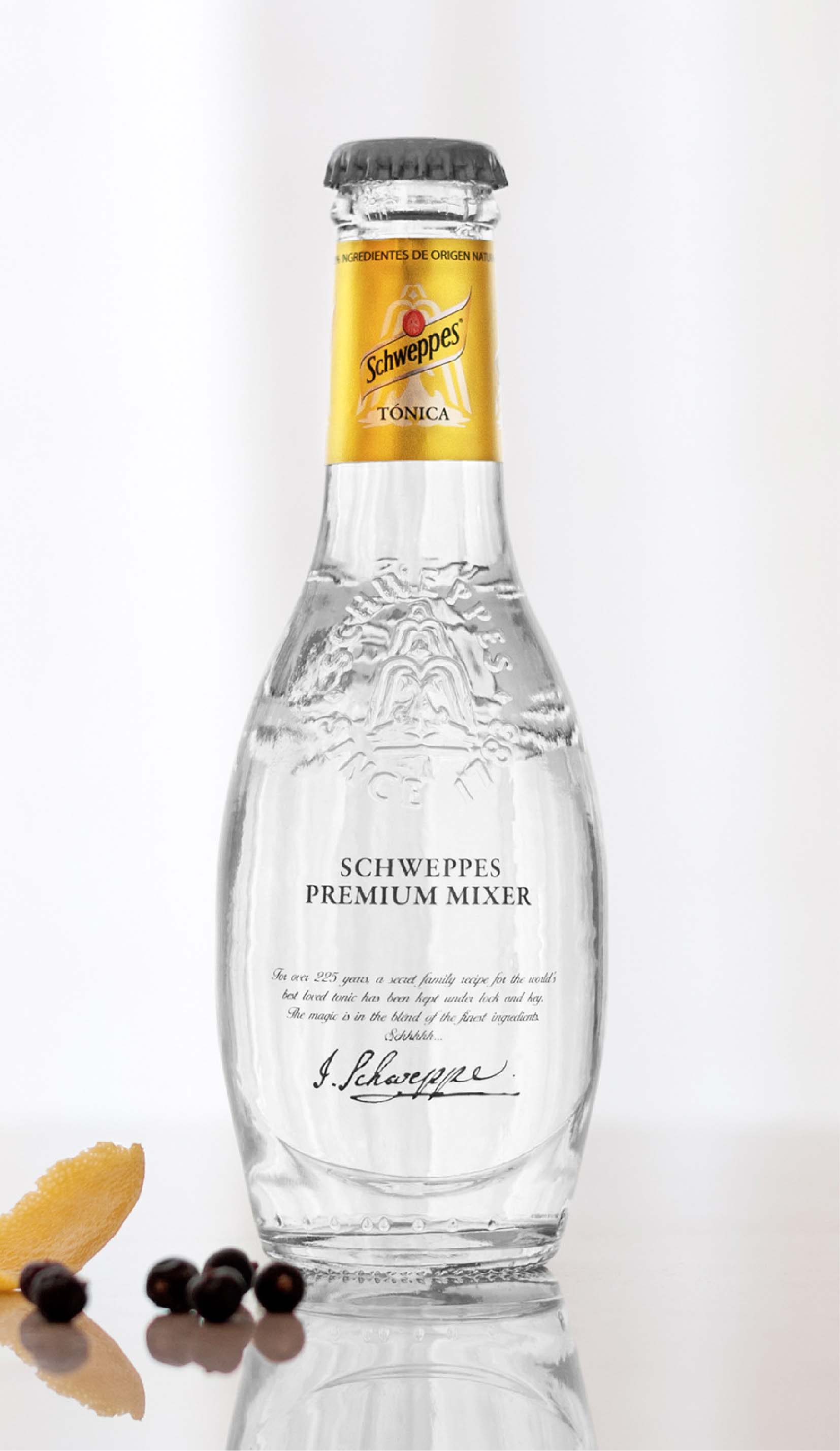

Industrial Packaging Design

Packaging is a highly demanding design typology, in terms of functionality, cost, innovation, visual impact and brand communication. Industrial packaging design must provide a solution to a multitude of design challenges, including the inexorable challenge of being part of the solution to the problem of environmental impact. Analyzing the technological and cost factors, the industrial designer will work on the formal creation of the packaging to deliver an attractive design capable of connecting with the consumer at the critical moment of purchase decision.

3

Manufacturing processes and technical constraints

An industrial design project must incorporate technical and manufacturing constraints from the initial approach. These will be determined according to the materials used, their processes and manufacturing constraints and must contemplate a cost-optimized design. A spectacular design that overlooks the technical constraints and their optimal manufacturing context is just an idea on paper and does not lead to a real success story.

The sum of manufacturing know-how, plus the mastery of formal, esthetic and visual aspects, represents the main value of industrial design.

4

Prototyping

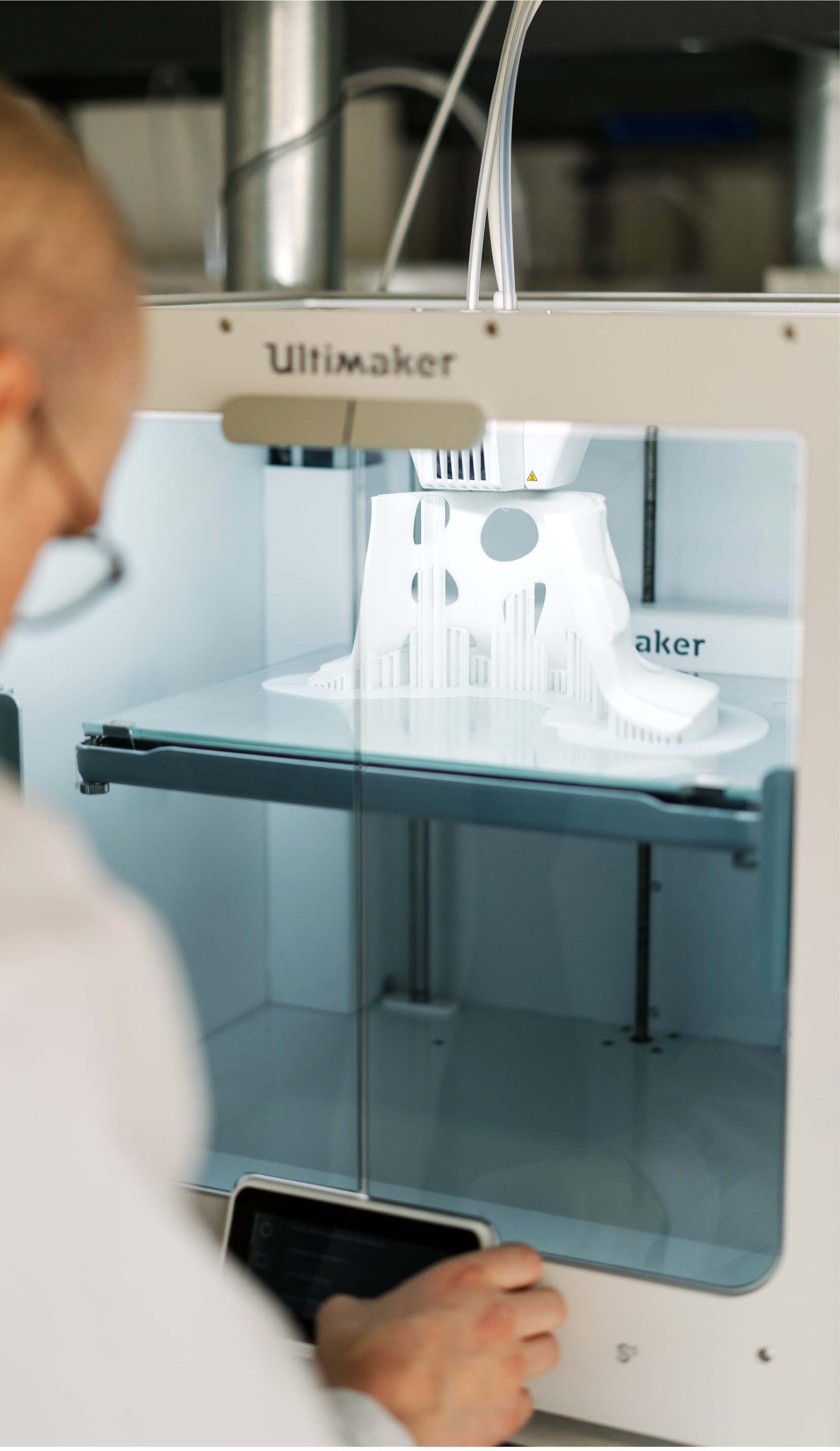

During various phases of an industrial design project, the modeling and prototyping phase is of vital importance to validate the functional and formal properties of the new design. With this validation, we will make design adjustments and avoid future problems in the manufacturing process. Similarly, these prototypes or mock-ups will allow us to physically validate the design, carry out market studies, and analyze it in comparison with the competition.

There are countless prototyping techniques depending on the needs of the project, such as 3D printing, CNR machining, or also through the use of artisanal techniques.

5

Sustainable materials

In the industrial design sector, we are immersed in an unstoppable paradigm shift. Plastics and their derivatives have been at the forefront of the industrial sector, but they can no longer be the solution. We work with suppliers and manufacturers who, after years of R&D, provide alternative materials that allow us to make the ecological transition.

New materials from sustainable, biodegradable, recycled and recyclable natural resources are the new protagonists of the so-called circular economy.

Industrial design must be the driving force for change in this new era of industry, acting as a bridge between technological innovations and major brands.

FAQS

-

What is the difference between industrial design and product design?

Academically, product design is a specific area of industrial design, but the two terms generally refer to the same discipline. They are basically the same. While industrial design relates to industry-related products such as automobiles, electronic components, computers, packaging, etc., we use the term product design for domestic projects such as the design of furniture, household products, toys, etc.

-

Does sustainable design require a major investment?

Nowadays, we find a wide variety of advanced materials and emerging technologies that allow us to manufacture more sustainable products without the need for a large investment. By opting for sustainability and the use of advanced materials, we can in many cases maintain the current manufacturing structure and only substitute the origin of the raw material with new alternative, renewable, biodegradable or recycled materials belonging to the new generation of sustainable materials.

-

Does industrial design only deal with industrially produced products?

No. Industrial design also undertakes projects that involve artisanal production processes. In the luxury sector or in limited edition products, craftspeople’s mastery and expertise in leather, wood, ceramics, blown glass, jewellery, etc. is constantly required. The diversity of applications of industrial design goes far beyond the explicitly industrial sector.

-

Why register industrial design intellectual property?

Industrial designs must be registered in the intellectual property register to prevent third parties from manufacturing and selling products that are a copy of the registered design. Intellectual property in industrial design protects product innovations that bring leadership to brands. When you copy the innovation of other products, you are also appropriating their values and generating confusion regarding the authenticity of the product among consumers.

-

What is re-styling in industrial design?

We talk about re-styling in industrial design when we improve the formal design of a product but preserve the essence of the predecessor design. In this way, we achieve an improvement in ergonomics, material optimization or a formal update, while maintaining the values of the original design. It would be indicated when the design strategy is to improve the current design without changing or losing the current brand values represented in the previous design.

-

What is the potential of 3D printing manufacturing?

3D printing technologies have brought about a revolution in industrial design, allowing prototypes to be created quickly, accurately and cost-effectively. This technology presents an enormous advantage for testing different design options. At the same time, major companies have implemented 3D printing in their production process and are using this technology to manufacture customized products without the need to invest in high-cost molds. This promises a paradigm shift in the industry that will enable new design and manufacturing rules.

Let's talk

Together,we cancreatesomethingextraordinary

We will collaborate to find the right answer and bring progress to your business and to the world.